Recently, Innoview's independently developed "AI Online Visual Monitoring Instrument" won first prize in the 2025 Highway Traffic Intelligent Equipment Technology Innovation Competition hosted by the China Highway Society, thanks to its groundbreaking oblique optical axis DIC technology and outstanding engineering application value! This is not only a full affirmation of Innoview's technological innovation capabilities by industry authorities, but also an important milestone for the field of intelligent transportation infrastructure monitoring to move towards the "AI vision era".

Breaking Technological Boundaries, Redefining Infrastructure Safety Monitoring

In the full lifecycle management of critical transportation infrastructure such as bridges, slopes, and tunnels, millimeter-level deformation often foreshadows significant safety hazards. EVE's AI online visual monitoring instrument innovatively integrates oblique optical axis DIC technology with artificial intelligence algorithms, achieving:

24/7 unattended monitoring: No reflective markers required, maintaining high stability even in complex environments;

Sub-millimeter displacement precision capture: Real-time deformation data output based on image algorithms, with 80% higher accuracy than traditional sensors;

Long-cycle dynamic tracking: Automatically establishes deformation theoretical models, providing continuous data support for structural health trend analysis.

Deep Integration and Application to Create a Smart Infrastructure Operation and Maintenance System

The award-winning technology has been successfully applied to Innoview's "Bridge Structural Safety and Health Monitoring System" and "Automated Slope Safety Monitoring System," forming a full-chain solution covering "monitoring-early warning-analysis-operation and maintenance":

▶ In bridge monitoring scenarios, the system uses a multi-dimensional visual perception network to achieve precise control over key indicators such as deflection, displacement, and cracks, and combines this with a BIM/GIS digital platform to construct a "health profile" of the bridge.

Application Case: Zhengzhou Hebei Medical University Overpass Safety Monitoring Project

In the Zhengzhou Hebei Medical University Overpass safety monitoring project, the system successfully achieved high-precision monitoring of bridge deflection deformation and vibration frequency. The project accurately captured a minute displacement of -1.074mm, with a frequency analysis accuracy of up to 0.00Hz, providing crucial data for the precise maintenance and scientific management of the bridge.

▶ In slope monitoring scenarios, the system uses AI vision instruments to capture micro-deformations of the sliding surface, providing a scientific basis for landslide early warning and mitigation decisions, effectively improving the ability to warn of major risks.

Application Case: Hua'an Slope Monitoring Project, Zhangzhou, Fujian

The Hua'an Slope Monitoring Project in Zhangzhou, Fujian, employs non-contact monitoring technology based on machine vision and AI. A single monitoring point can comprehensively cover the entire slope area, including the top, surface, and toe, with an effective monitoring width reaching hundreds of meters depending on the slope's scale. Compared to the traditional method of densely deploying contact sensors on the slope, this solution significantly simplifies installation and deployment, offering significant advantages in terms of wider coverage and lower overall cost.

▶ In tunnel monitoring scenarios, the system utilizes an AI-powered online visual monitoring instrument to accurately capture the micro-deformation and convergence trends of the tunnel lining, providing a scientific basis for structural stability assessment and potential risk warning, significantly improving the ability to provide early warning of tunnel safety risks.

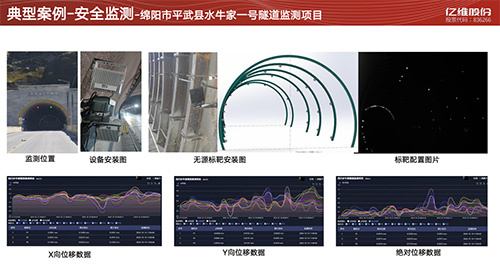

Application Case: Monitoring Project of Shuiniujia No. 1 Tunnel in Pingwu County, Mianyang City

The monitoring project of Shuiniujia No. 1 Tunnel in Pingwu County, Mianyang City, implemented high-precision monitoring of the structural stability of the tunnel after construction. The system successfully recorded a tunnel convergence displacement of 0.072 mm. The obtained data significantly outperformed traditional total stations in terms of stability, providing a more accurate and reliable technical basis for assessing the structural health and long-term safety of the tunnel.

Innoview is committed to integrating the "Internet + Intelligent Monitoring" concept into engineering practice. The AI visual monitoring technology that won this award is the core engine driving our transformation of transportation infrastructure operation and maintenance from "passive response" to "proactive early warning," based on the principle of "full coverage and grid-based management." In the future, we will continue to deepen the integration of AIoT, cloud computing, and professional knowledge to provide the industry with smarter and more reliable digital infrastructure management solutions.

Honors testify to our strength; innovation never stops. Innoview is willing to work hand in hand with industry partners to jointly build a solid safety defense line for transportation infrastructure and inject technological momentum into the construction of a strong transportation nation!

Innoview – Building Safe and Intelligent Digital Infrastructure

Note: The technical systems mentioned in this article have been successfully applied to key bridge and high slope operation and maintenance projects in multiple provinces and cities. For more information on scenario examples and technical details, please contact the Innoview expert team.

2025-10-27 18:00:00

2025-10-27 18:00:00  times

times