Slope monitoring

|

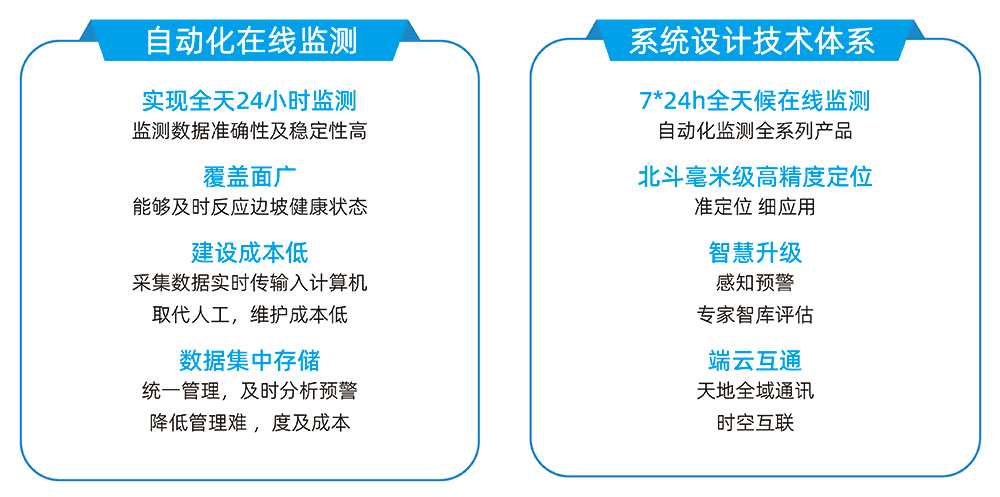

System Introduction |

Highway slopes, especially in mountainous areas, present complex engineering conditions, numerous influencing factors, and significant maintenance challenges. Slope deformation and damage can severely disrupt highway operation and management. Traditional slope monitoring relies primarily on on-site inspections by maintenance personnel, using manual visual assessments to monitor and determine slope safety, which fails to provide a timely and comprehensive understanding of potential safety risks.

The dynamic slope monitoring system is a comprehensive monitoring system integrating structural analysis and calculation, computer technology, communication technology, network technology, and sensor technology. It can monitor surface displacement, deep displacement, crack displacement, rainfall, and soil moisture. This system is a professional online real-time monitoring system for comprehensive safety slopes, achieving digital and networked slope monitoring.

|

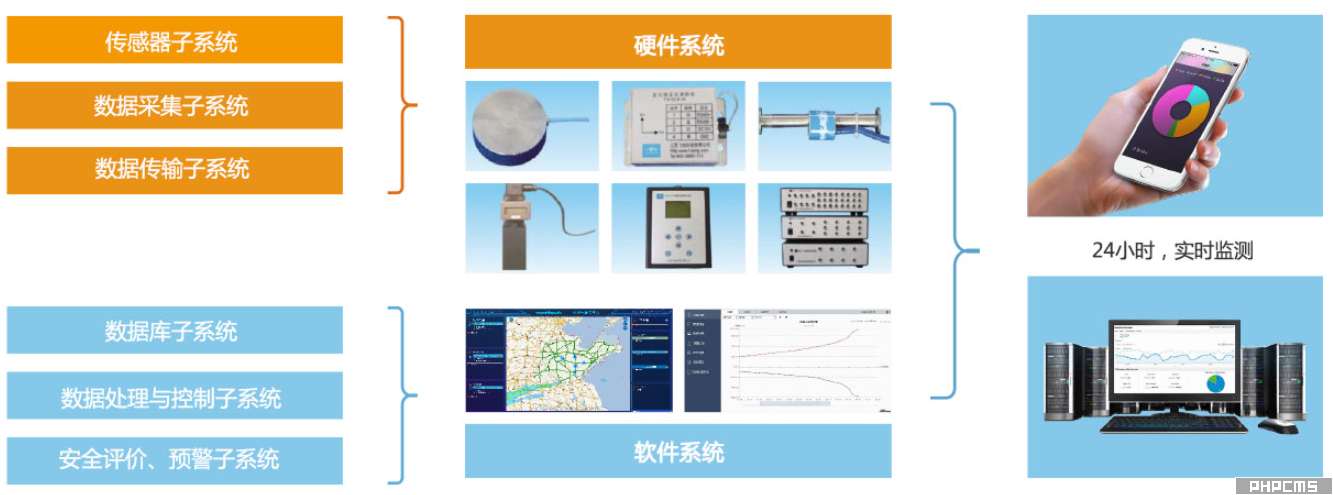

System Composition |

The slope dynamic monitoring system utilizes high-precision, high-reliability monitoring sensors to effectively monitor slope stability. Monitoring data reflects factors that may lead to slope instability, including surface displacement, cracks, and rainfall (snowfall). It determines monitoring and early warning thresholds and designs and standardizes control values such as deformation amount and rate of change. Monitoring data, combined with macroscopic deformation and failure indicators, is used for comprehensive judgment to determine the safety of the slope structure. The system also monitors the bearing capacity, operational status, and durability of the support structure to meet safe operation requirements. Furthermore, based on the monitoring objects and objectives, and adhering to the principles of demand and economy, waste is avoided.

System Composition Diagram

System Composition Diagram

| Easy to install | High stability | |

| No complicated cables required | Equipped with temperature and humidity measurement and compensation functions | |

| Solar power can be used | Built-in gyroscope can eliminate the effects of device displacement and vibration | |

| Wireless data transmission is possible | Combined with AI algorithms, measurements can still be taken even in low visibility conditions such as wind, frost, rain, and snow | |

| Easy to operate | Comprehensive data | |

| After initialization, it can automatically identify and measure without human intervention | It can measure the displacement of multiple points simultaneously in real time with high precision | |

| Data can be transmitted in real time to the data collector and automatically uploaded to the cloud platform | It can simultaneously measure and visually display two-dimensional (horizontal and vertical) displacement | |

| Real-time data can be viewed via web browser or mini-program | It can obtain deflection values, filtering functions, baseline shift, impulse coefficient, power spectrum, and frequency range | |

| Early warning feedback can be provided according to customer requirements | The recording function provides the option for subsequent reanalysis |

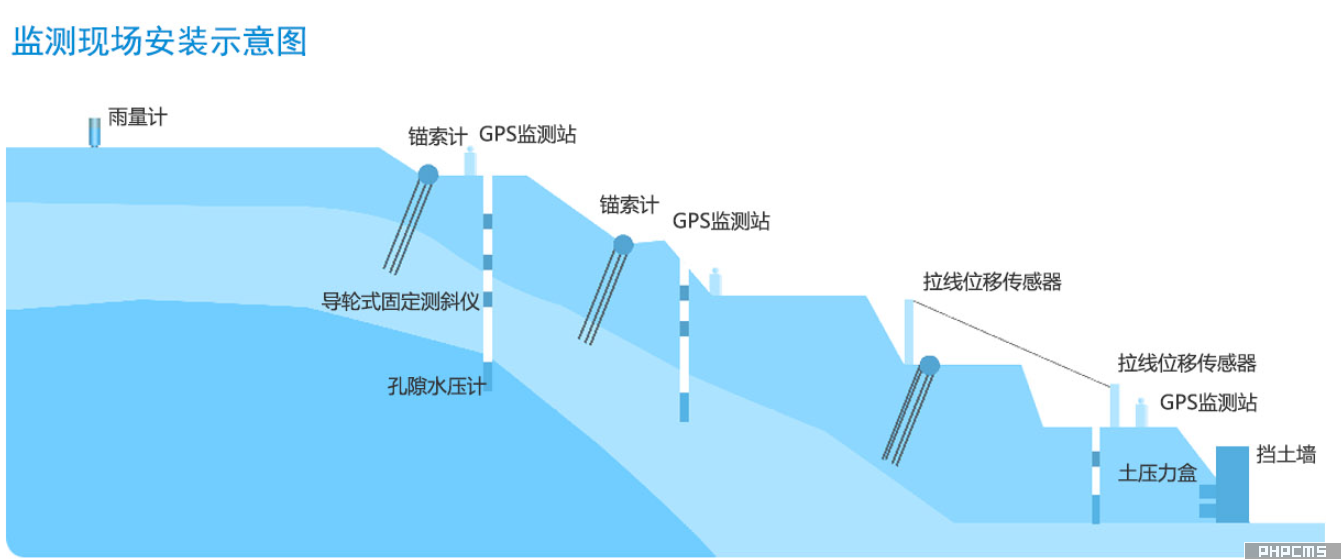

Monitoring site installation diagram

Integrated Positioning: Employs a comprehensive positioning system combining BeiDou, GPS, and GLONASS.

Accurate data: The positioning accuracy of both horizontal and vertical displacement is within 1mm.

Submillimeter-level positioning: A perfect combination of advanced board technology and big data processing technology.

Continuous monitoring: The structural condition is monitored without interruption to obtain continuous and complete health information for highway slopes.

Improved efficiency: It can eliminate manual measurement in the monitoring process, shorten manual working time, and improve work efficiency.